1. What’s Compact Crawler Boom Lift?

The compact crawler boom lift is an aerial work platform that features a platform at the end of the boom for workers to stand on. The boom can be extended vertically and horizontally to reach high places, making it a versatile piece of equipment that can be used for tasks such as maintenance, construction, and repair.

What sets a compact crawler boom lift apart from other types of boom lifts is its crawler chassis. The chassis is equipped with tracks that allow the lift to easily traverse rough and uneven terrain. This makes crawler boom lifts ideal for outdoor use on construction sites, industrial facilities, and other locations where traditional wheeled boom lifts are difficult to maneuver.

Overall, a compact crawler boom lift's combination of height, stability, and mobility make it a valuable tool for accessing elevated work areas in a variety of environments.

Specifications Table

| Specification | Description |

|---|---|

| Working Height | 10m - 22m (33ft - 72ft) |

| Horizontal Outreach | 5m - 20m (16ft - 65ft) |

| Platform Capacity | 200kg - 450kg (440lbs - 990lbs) |

| Platform Size | 1.2m x 0.8m (3.9ft x 2.6ft) |

| Stowed Height | 2m - 2.5m (6.6ft - 8.2ft) |

| Weight | 3,000kg - 6,000kg (6,600lbs - 13,200lbs) |

| Drive System | Dual-speed crawler tracks with 360-degree rotation |

| Power Source | 48V DC battery, Diesel engine, or Hybrid (Battery + Diesel) |

| Gradeability | Up to 30% (suitable for sloped terrain) |

| Outrigger System | Automatic leveling with multiple angle settings |

| Turning Radius | Zero turning radius for tight space maneuverability |

| Control System | Proportional joystick control for precise movement |

| Safety Features | Emergency stop, overload protection, tilt sensors, and anti-slip tracks |

2. The Specification Of Compact Crawler Boom Lift

Model | Platform height(m) | Working height(m) | Load capacity(kg) |

THZBLD-10 | 10 | 12 | 200 |

THZBLD-12 | 12 | 14 | 200 |

THZBLD-14 | 14 | 16 | 200 |

THZBLD-16 | 16 | 18 | 200 |

THZBLD-18 | 18 | 20 | 200 |

THZBLD-20 | 20 | 22 | 200 |

Power | AC, DC, Diesel, Petrol | ||

Safety feature | *Cylinders on the arms have explosion-proof function *Cylinders on the outriggers are equipped with hydraulic locks *Rear light, strobe light on each outrigger *Tool box, safety belt and control panel on the basket *All operations can be controlled by remote control *Emergency descend valve on each arm *Remote, automatic outrigger(handle operation and level tester) *Overload protection, Leakage protection *Automatic leveling system and tilt alarm *Electromagnetic brake Assist system *Folding outriggers with larger range to ensure user’s safety *Lifting speed adjustable *PLC touch screen control system *Electrophoresis, strong anti-rust function *Safety buttons on upper & lower control | ||

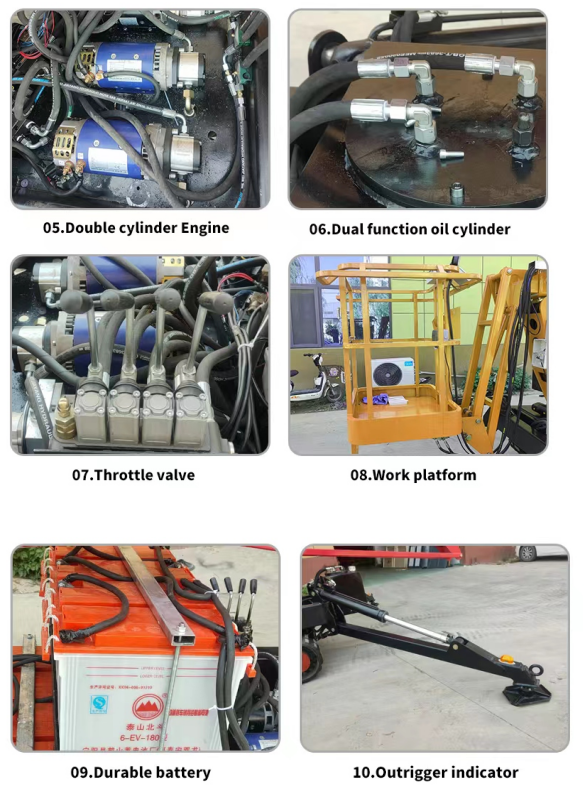

Parts display |

| ||

Accessories List

| Accessory | Description |

|---|---|

| Platform Extension | Allows for increased reach and workspace, extending the platform size. |

| Power Outlets on Platform | Provides power for tools and equipment directly from the platform. |

| Non-Marking Tracks | Ideal for indoor use, preventing marks on sensitive flooring. |

| Work Lights | LED lights mounted on the platform for better visibility in low-light conditions. |

| Safety Harness Anchor Points | Provides secure points for attaching safety harnesses. |

| Remote Control System | Allows for operation of the boom lift from a distance, useful for setup. |

| Platform Tool Tray | Customizable tray for holding tools and small parts during work. |

| Cold Weather Package | Includes battery heaters and hydraulic oil warmers for cold environments. |

| Outrigger Pads | Provides additional stability on soft or uneven ground. |

| Motion Alarm and Beacon | Alerts nearby workers when the lift is in motion or elevated. |

3. The Advantages Of Compact Crawler Boom Lift

(1) Small shape, beautiful appearance, small storage size, flexible and convenient to move;

(2) Rubber or steel tracks have less pressure on the ground and can travel and work on any road surface, especially indoor floors;

(3) The track height and width can be adjusted, which increases the approach angle and departure angle of the track, and can travel on any uneven road surface with a climbing ability of 30%;

(4) The working platform can work around obstacles;

(5) Remote control operation, easy to operate;

(6) Concentric telescopic technology ensures that the telescopic arm can be extended and retracted freely and reduces eccentric shaking;

(7) All pipelines are built-in to avoid sun and rain, or being hung by foreign objects;

(8) The working platform is hydraulically automatically leveled to ensure that the working platform is always level no matter where the working arm is;

(9) It has an emergency stop device and an overload protection device;

(10) All functions of the working platform can be completed from the platform;

(11) It can travel on any uneven ground, such as muddy ground;

4.Manufacturing Standards

| Standard | Description |

|---|---|

| ISO 9001: Quality Management | Ensures consistent manufacturing processes and high-quality standards. |

| EN 280: Aerial Work Platforms | Specifies safety and performance standards for mobile elevating work platforms (MEWPs) in the EU. |

| CE Marking (Europe) | Compliance with European safety, health, and environmental regulations. |

| ANSI A92.20 (USA) | Design, safety, and testing requirements for aerial work platforms in the United States. |

| UL 583: Electric Lift Trucks | Safety standards for electric motors and batteries used in lifts. |

| ISO 12100: Safety of Machinery | Risk assessment and safety design measures to ensure operator safety. |

| RoHS Compliance | Ensures that no hazardous substances are used in electrical components. |

| ISO 14001: Environmental Management | Focuses on sustainable manufacturing practices to reduce environmental impact. |

| ASTM A36: Structural Steel | Standards for steel used in the construction of the lift’s frame and boom. |

| ISO 4413: Hydraulic Systems | Sets guidelines for designing and testing hydraulic systems for safe and efficient operation. |

5. User Manual: Operating and Maintaining a Compact Crawler Boom Lift

1. Operation Instructions

Pre-Operation Inspection: Inspect the lift for any visible damage, check hydraulic fluid levels, and ensure that the batteries are fully charged.

Platform Entry: Safely enter the platform and secure the safety gate. Attach a safety harness to the designated anchor points.

Stabilizing the Lift: Deploy the outriggers using the control panel to ensure the lift is level and stable before elevating.

Using the Joystick Control: Use the joystick to control the lift’s movement and elevation. Ensure smooth and gradual adjustments to avoid sudden jerks.

Operating in Crawler Mode: When moving the lift, lower the boom to the stowed position and navigate using the crawler tracks.

Emergency Procedures: Familiarize yourself with the emergency stop button and manual lowering system for use in case of power failure.

2. Safety Precautions

Do Not Overload: Always adhere to the platform's maximum weight capacity, including the weight of the operator and any tools or materials.

Avoid Inclined Surfaces: Operate the lift on flat surfaces whenever possible. If working on an incline, ensure that the outriggers are securely positioned.

Use Safety Harnesses: Always wear a safety harness when working at height and attach it securely to the designated anchor points.

3. Maintenance Guidelines

Daily Maintenance: Clean the platform and control panel, inspect the tracks for wear, and check hydraulic fluid levels.

Weekly Maintenance: Test the battery, lubricate all moving parts, and inspect the joystick and control systems for proper function.

Monthly Maintenance: Check all hydraulic hoses for leaks, inspect the boom structure for any signs of stress or damage, and perform a full battery recharge.

Annual Maintenance: Engage a certified technician for a complete inspection of the lift, including the hydraulic system, electrical components, and structural integrity.

The Compact Crawler Boom Lift is a powerful and adaptable tool for accessing elevated work areas, especially in rough or confined environments. With a range of features designed to enhance safety, maneuverability, and user comfort, it offers an effective solution for both indoor and outdoor applications. Understanding its specifications, available accessories, and proper usage ensures optimal performance and a safe working environment. Whether for construction, maintenance, or specialized tasks, this lift is a valuable addition to any worksite.

6. How To Purchase A Compact Crawler Boom Lift?

JNHC Lift is a professional manufacturer specializing in Compact Crawler Boom Lifts. With advanced technology and a commitment to quality, JNHC delivers durable and reliable lifts designed for easy maneuverability in tight spaces. Our lifts offer enhanced safety and efficiency, making them ideal for a wide range of indoor and outdoor applications. If you want to purchase compact crawler boom lift, please tell us the lifting height & machine power & incoterms(EXW or FOB or CIF, etc, it is FCL shipping) you need, then our sales manager will contact you immediately; If you decide to purchase it from us, our sales manager will send you a proforma invoice with our bank information, then you can pay the deposit, after we received the deposit, we will start production; When production will finished, we will send the product photos or videos, then you can pay the balance, we will arrange the shipment after balance arrived. After the goods arrived your designated seaport, you can process the custom clearance and then pick up the boom lift.

678.webp)

232.webp)

824.webp)

756.webp)

633.webp)