Vertical mast lifts and scissor lifts are two of the most commonly used aerial work platforms (AWPs) across various industries. Both are designed to elevate workers, tools, or materials to perform tasks at heights safely. However, their structural designs, functionalities, and applications vary significantly. This article provides a detailed comparison between vertical mast lifts and scissor lifts, highlighting their differences in design, applications, advantages, and limitations.

What is a Vertical Mast Lift?

A vertical mast lift is a compact and lightweight aerial work platform with a single or double vertical mast system. It is designed to elevate a small platform vertically, typically accommodating one person and minimal tools.

Key Characteristics

Structure: Consists of a stable base and a telescopic or articulated mast.

Compact Design: Narrow and maneuverable, ideal for tight spaces.

Height Range: Usually extends up to 40 feet.

Load Capacity: Generally supports 300–500 pounds.

Common Applications

Vertical mast lifts are used in industries and tasks requiring high precision and limited mobility:

Maintenance Work: Ideal for changing lights, cleaning windows, or repairing indoor fixtures.

Retail and Warehousing: Stocking shelves or accessing inventory in confined areas.

Healthcare Facilities: Suitable for maintenance in hospitals or other narrow spaces.

What is a Scissor Lift?

A scissor lift is a type of aerial platform that moves vertically through a cross-braced mechanism, resembling the action of scissors. It is designed to provide a broader platform and higher load capacities than vertical mast lifts.

Key Characteristics

Structure: Features a large base and scissor-like arms for vertical movement.

Wide Platform: Can accommodate multiple workers and equipment.

Height Range: Typically extends up to 60 feet or more.

Load Capacity: Supports 500–2,000 pounds or more.

Common Applications

Scissor lifts are versatile and used in various industries requiring heavy lifting and wide platforms:

Construction Sites: Assisting in building, painting, or installation tasks.

Manufacturing Facilities: Supporting assembly lines and maintenance.

Outdoor Projects: Used for tree trimming, signage, or outdoor repairs.

Key Differences Between Vertical Mast Lift and Scissor Lift

| Aspect | Vertical Mast Lift | Scissor Lift |

|---|---|---|

| Design | Narrow, compact, and lightweight | Wider, with cross-braced lifting arms |

| Platform Size | Small, single-person platform | Larger, accommodates multiple workers |

| Height Range | Up to 40 feet | Up to 60 feet or more |

| Load Capacity | 300–500 pounds | 500–2,000 pounds or more |

| Maneuverability | Highly maneuverable, fits tight spaces | Requires more room for movement |

| Applications | Indoor tasks and light maintenance | Heavy-duty tasks and outdoor use |

| Power Source | Electric or battery-powered | Electric, battery, or diesel-powered |

| Stability | Stable for lightweight applications | Designed for heavy loads and high stability |

Advantages and Disadvantages

Both vertical mast lifts and scissor lifts are essential tools for elevating workers, tools, or materials safely. However, their advantages and disadvantages vary depending on their design, functionality, and applications. Below is a detailed analysis to help you understand their strengths and limitations.

Vertical Mast Lift

Advantages:

Compact and Lightweight: Ideal for use in confined indoor spaces or areas with limited access.

Easy Maneuverability: Can navigate narrow aisles, doorways, and elevators with ease.

Cost-Effective: More affordable than scissor lifts, both in purchase and operation.

Low Maintenance: Fewer mechanical components lead to reduced maintenance costs.

Disadvantages:

Limited Load Capacity: Not suitable for tasks requiring heavy lifting or multiple workers.

Lower Height Range: Restricted to tasks requiring heights up to 40 feet.

Narrow Platform: Limited workspace for tools or additional personnel.

Scissor Lift

Advantages:

High Load Capacity: Supports heavy tools, materials, and multiple workers.

Versatile Platform Size: Provides ample workspace, enhancing efficiency for large projects.

Greater Stability: Excellent for outdoor tasks and heavy-duty operations.

Extended Height Range: Can reach up to 60 feet or more, accommodating high-altitude tasks.

Disadvantages:

Bulky Design: Requires more storage space and cannot navigate tight areas easily.

Higher Cost: More expensive to purchase and maintain compared to vertical mast lifts.

Reduced Maneuverability: Limited movement in confined spaces or uneven terrain.

Understanding these advantages and disadvantages will help you select the right lift for your specific needs, ensuring safety, efficiency, and cost-effectiveness.

Choosing Between Vertical Mast Lift and Scissor Lift

When selecting the right aerial work platform for your project, the decision between a vertical mast lift and a scissor lift depends on factors like workspace constraints, height and load requirements, and specific applications. Below is a guide to help you choose the most suitable lift for your needs.When deciding between a vertical mast lift and a scissor lift, consider the following factors:

Application Type:

Choose a vertical mast lift for indoor maintenance, retail, or warehouse tasks requiring precision in small spaces.

Opt for a scissor lift for heavy-duty outdoor projects, construction, or tasks involving multiple workers.

Load and Height Requirements:

If the job involves lifting heavy loads or working at extreme heights, a scissor lift is the better choice.

For lighter loads and moderate heights, a vertical mast lift suffices.

Space Constraints:

Vertical mast lifts excel in narrow or crowded environments.

Scissor lifts are better suited for open areas with ample space.

Budget:

Vertical mast lifts are more affordable, making them a cost-effective option for light-duty tasks.

Scissor lifts, while more expensive, provide better value for demanding applications.

Mobility Needs:

Vertical mast lifts offer superior mobility, especially in indoor settings.

Scissor lifts require more effort to maneuver and are less suited for confined spaces.

Choosing between a vertical mast lift and a scissor lift depends on your project’s specific needs. Vertical mast lifts are ideal for indoor, light-duty tasks requiring precision and mobility, while scissor lifts are better suited for heavy-duty, outdoor, or multi-person projects. Assess your requirements for load capacity, height, space, and budget to make the best choice for your work environment.

Future Trends in Aerial Work Platforms

Both vertical mast lifts and scissor lifts are evolving with technological advancements, enhancing their usability and safety:

Electric Models: Growing preference for environmentally friendly electric lifts over diesel-powered variants.

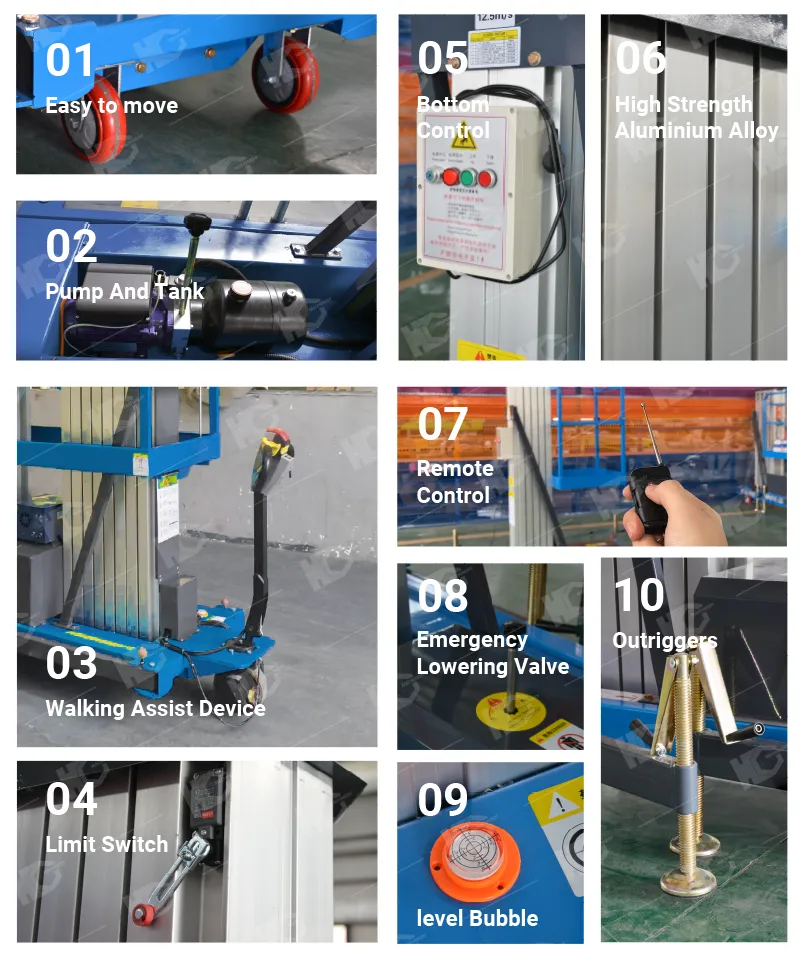

Enhanced Safety Features: Advanced sensors, automatic brakes, and stability controls.

Compact Designs: Improved maneuverability in both types of lifts.

Remote Control Operation: Increasing integration of remote and automated controls for better efficiency.

Conclusion

Vertical mast lifts and scissor lifts each serve distinct roles in the aerial work platform market. While vertical mast lifts excel in compact, lightweight, and indoor applications, scissor lifts are better suited for heavy-duty tasks requiring larger platforms and higher load capacities.

Understanding the specific needs of your project is essential to make the right choice. By analyzing factors like application type, load capacity, maneuverability, and budget, you can ensure that your selected lift provides the best performance and safety for your work environment.