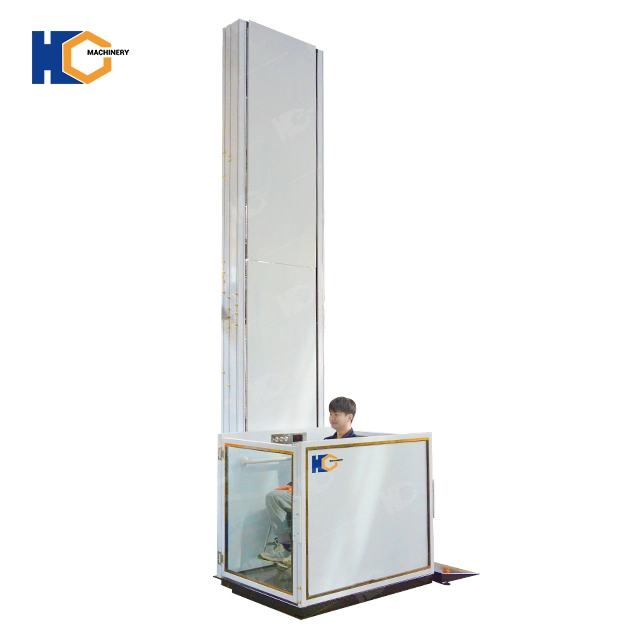

What is a Scissor Lift?

Scissor lifts are mechanical devices used in various industries for lifting and accessing elevated areas. They come in different sizes and configurations to meet different needs.

A scissor lift is a type of equipment that resembles a pair of scissors when extended or retracted. Just like the word "scissor" which in English is pronounced /ˈsɪzə(r)/ and is used to describe a cutting tool with two blades that pivot around a central point, a scissor lift consists of multiple sections that can expand and contract to raise or lower a platform.

Configurations of scissor lifts can vary greatly. Some are designed for indoor use and are compact and easy to maneuver in confined spaces. Others are built for outdoor applications and may have more robust frames and larger lifting capacities. The configurations are determined by factors such as the intended use, the weight and size of the objects to be lifted, and the working environment.

For example, in a warehouse setting, a scissor lift might be configured to have a larger platform area to accommodate pallets of goods. In a construction site, a scissor lift might be equipped with safety features such as guardrails and non-slip surfaces to ensure the safety of workers.

The different configurations of scissor lifts make them versatile tools that can be adapted to a wide range of tasks and industries. Whether it's for maintenance work in a factory, painting a high ceiling in a building, or installing electrical fixtures in a large commercial space, scissor lifts offer a practical solution for accessing elevated areas safely and efficiently.

Weight of Scissor Lifts by Height

The weight of a scissor lift can vary significantly depending on several factors. Generally, scissor lifts can range from a few hundred pounds to several thousand pounds. The materials used in construction play a crucial role in determining the weight. For example, if high-strength but heavier materials are employed, the scissor lift will weigh more. On the other hand, lighter materials may result in a lower weight but might affect the lift's capacity and durability.

Here’s a table outlining the typical weight ranges for different types of scissor lifts based on their applications and specifications:

10 ft Scissor Lift

Weight: Approximately 1,500 to 2,000 lbs (680 to 907 kg)

Use Case: Ideal for indoor tasks like warehouse maintenance or retail stock management. These compact lifts are lightweight and easy to maneuver.

19 ft Scissor Lift

Weight: Around 2,500 to 3,500 lbs (1,134 to 1,588 kg)

Use Case: Suitable for medium-height tasks such as ceiling repairs or electrical work in larger indoor spaces.

20 ft Scissor Lift

Weight: Typically 3,000 to 4,000 lbs (1,361 to 1,814 kg)

Use Case: Commonly used in construction and maintenance for tasks like painting, window cleaning, or HVAC installations.

26 ft Scissor Lift

Weight: Approximately 5,000 to 6,500 lbs (2,268 to 2,948 kg)

Use Case: A versatile option for both indoor and outdoor projects, including building maintenance and facility upgrades.

30 ft Scissor Lift

Weight: Around 6,000 to 8,000 lbs (2,722 to 3,629 kg)

Use Case: Designed for higher-reaching tasks such as exterior building repairs or large-scale installations.

32 ft Scissor Lift

Weight: Typically 7,000 to 9,000 lbs (3,175 to 4,082 kg)

Use Case: Used in industrial settings or construction sites where greater height and stability are required.

40 ft Scissor Lift

Weight: Approximately 10,000 to 12,000 lbs (4,536 to 5,443 kg)

Use Case: Ideal for heavy-duty outdoor projects, such as bridge maintenance or large-scale construction.

45 ft Scissor Lift

Weight: Around 12,000 to 14,000 lbs (5,443 to 6,350 kg)

Use Case: Suitable for high-reach tasks in open areas, such as stadium maintenance or industrial facility repairs.

50 ft Scissor Lift

Weight: Typically 14,000 to 16,000 lbs (6,350 to 7,257 kg)

Use Case: Designed for specialized projects requiring significant height, such as high-rise building maintenance or large-scale event setups.

60 ft Scissor Lift

Weight: Approximately 18,000 to 20,000 lbs (8,165 to 9,072 kg)

Use Case: Used for extreme-height tasks, such as telecommunications tower maintenance or large industrial installations.

The size of the platform is another important factor. A larger platform will naturally add to the weight of the scissor lift. Additionally, features like safety rails or power sources can also contribute to the overall weight. Safety rails made of sturdy materials will increase the weight, while a more powerful power source might be heavier as well.

In conclusion, when considering the weight of a scissor lift, one must take into account the materials, platform size, and additional features to get an accurate estimate.

Dimensions of a Scissor Lift

The dimensions of a scissor lift play a crucial role in determining its usability and suitability for different applications. Platform size is an important consideration. For example, a scissor lift with a smaller platform size might be ideal for tasks in confined spaces or for single-person operations. On the other hand, a larger platform size can range from several square feet to accommodate several people and equipment simultaneously. This is particularly useful in warehouse settings where pallets of goods need to be transported or in construction sites where multiple workers need to access elevated areas together.

The height when extended is another significant dimension. Scissor lifts can reach heights ranging from a few feet to several stories high. This allows for access to different levels in buildings, for maintenance work on high ceilings, or for construction tasks at elevated heights. The extended height gives workers the ability to perform tasks that would otherwise be difficult or impossible to reach safely.

The overall footprint of a scissor lift is also essential. It determines where the lift can be used and how much space it will take up. A smaller footprint is beneficial for indoor use where space is limited, while a larger footprint might be more suitable for outdoor applications where there is more space available. For instance, in a factory or a commercial building, the footprint needs to be considered to ensure that the lift can fit through doorways and maneuver around obstacles.

In conclusion, understanding the dimensions of a scissor lift is crucial for choosing the right equipment for a specific task. Whether it's considering the platform size, extended height, or overall footprint, these dimensions impact the efficiency and safety of operations.

A professional manufacturer can provide suitable solution for your using conditions.

Technical Specifications

Power Source

Hydraulic scissor lifts are known for their reliability and strength, because hydraulic systems, as actuators, are used in all industrial equipment and can lift large weights without requiring complex maintenance.

Scissor lifts offer several power source options, each with its own set of characteristics. Electric-powered scissor lifts, including AC power and battery power, are a popular choice for indoor applications. They are user-friendly and have a relatively low environmental impact as they produce no emissions. This makes them ideal for environments where emissions need to be minimized, such as warehouses, shopping malls, and office buildings. However, electric lifts may have limited power output and require a nearby power source, which can restrict their mobility in some situations.

Diesel-powered scissor lifts, on the other hand, provide more power and are suitable for outdoor use. They can handle tougher terrains and longer distances. However, they produce emissions and are typically louder than electric lifts. This can be a concern in noise-sensitive areas or when working in close proximity to people.

Lifting Capacity

The lifting capacity of a scissor lift is another important specification to consider. This refers to the maximum weight that the lift can safely support. Lifting capacities can range from a few hundred pounds to several tons. The lifting capacity depends on various factors such as the design of the lift, the materials used, and the power source. For example, a scissor lift with a stronger frame and a more powerful power source will generally have a higher lifting capacity. When choosing a scissor lift, it is essential to determine the maximum weight that will be lifted and select a lift with an appropriate lifting capacity. This will ensure the safety of the operators and prevent damage to the equipment.

The design of the lift plays a significant role in determining its lifting capacity. A scissor lift with a stronger frame and more robust construction is generally capable of handling heavier loads. The materials used in the construction also matter. High-quality steel and other durable materials can increase the lifting capacity while ensuring the safety and stability of the lift.

The power source also affects the lifting capacity. A more powerful power source, such as a larger engine or a stronger hydraulic system, can enable the lift to handle heavier weights. For example, a hydraulic-powered scissor lift may have a higher lifting capacity compared to an electric-powered one due to its greater power output.

When choosing a scissor lift, it is essential to determine the maximum weight that will be lifted and select a lift with an appropriate lifting capacity. This will not only ensure the safety of the operators but also prevent damage to the equipment and potential accidents.

Safety Features

Scissor lifts are equipped with a variety of safety features to protect the operators and those around them. These can include safety rails, emergency stop buttons, overload protection, and stability controls. Safety rails are one of the most important safety features. They provide a physical barrier to prevent operators from falling off the platform. These rails are typically made of sturdy materials and are designed to withstand impact. They can be adjusted or removed depending on the specific requirements of the job.

Emergency stop buttons are another crucial safety feature. Located on the control panel, these buttons can be pressed in case of an emergency to immediately stop the lift. This can prevent accidents and injuries when unexpected situations arise.

Overload protection is also essential. This feature prevents the lift from being overloaded, which can cause damage to the equipment and pose a significant safety hazard. When the lift reaches its maximum weight capacity, the overload protection system will activate, preventing further loading.

Stability controls ensure that the lift remains stable during operation. These controls can include sensors that detect changes in the lift's position or weight distribution and adjust the lift's operation accordingly. For example, if the lift becomes unstable due to uneven terrain or excessive weight on one side, the stability controls will activate to prevent tipping.

These safety features work together to provide a safe working environment for operators using.

How to Choose the Right Scissor Lift

The first step is to determine the lifting height and the maximum load capacity, which is the biggest factor determining the scissor lift price. Secondly, it is necessary to choose the appropriate power and wheels according to the usage scenario, such as using all terrain tires or tracks on uneven ground. Finally, choose the appropriate equipment based on your budget, such as a fully self-propelled scissor that is more expensive than a trailer scissor.

So if you are considering purchasing a scissor lift, it is best to contact a professional manufacturer, let us know your specific needs, and recommend equipment that is suitable for you.

Conclusion

The weight of a scissor lift varies significantly based on its height and design. From compact 10 ft models weighing around 1,500 lbs to robust 60 ft lifts tipping the scales at 20,000 lbs, there’s a scissor lift for every need. By understanding the weight specifications, you can make an informed decision that ensures safety, efficiency, and productivity on your job site. Always consult the manufacturer’s specifications and guidelines to select the right lift for your project.

812.webp)