1. What’s the scissor lift?

Scissor lift is a widely used aerial work platform that uses a cross-connected folding support mechanism to raise and lower the platform lifting platform that uses hydraulic cylinders to raise and lower the platform in a vertical direction. Scissor is commonly used in construction, maintenance and other industries to provide workers with a safe and stable aerial work platform. Scissor lifts can be driven by DC, AC, or diesel, and have different load capacities and platform sizes depending on the lifting height to meet different work requirements. Its working principle is similar to the opening and closing movement of scissors. It consists of two crossed metal arms, which are controlled by hydraulic or electric systems to achieve the lifting function. They can improve the efficiency of cargo handling and provide a convenient vertical transportation method.A scissor lift consists of a series of connected supports that extend and retract in a scissor motion to raise and lower the platform. The hydraulic system provides the power for the lift to move and control the height adjustment.

2. What are the types of scissor lifts?

There are two types of scissor lifts, fixed scissor lifts and mobile scissor lifts, both of which consist of a scissor structure, chassis, and platform. The scissor structure ensures that the lift is stable and durable.

Fixed scissor lifts are often used to transport heavy objects to another floor, like a cargo lift. This is a customized product, color, size, load capacity, lifting height, voltage, etc... can all be customized according to your requirements.

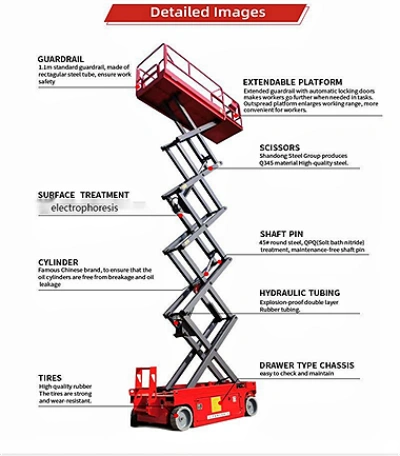

Mobile scissor lift is divided into mobile scissor lift and self-propelled scissor lift, it has 4 wheels, so you can easily move or drive it. Mobile scissor lift can only be towed to move, but you can drive the self-propelled scissor lift to move it, of course, the price of the two is quite different. This model is used for aerial work, such as ceiling maintenance, window cleaning, house building, etc... This is a standard product, the standard height is 4m 6m 8m 10m 12m 14m 16m 18m scissor lift. The size and power are also standard, but we TUHE also accept OEM and ODM production.

(1) Stationary scissor lift: it is a fully customized product, including the lifting height, platform size, load capacity, color, so if you need this machine, please tell these parameters to your sales manager, then he/she will quote you;

(2) Mobile scissor lift: it is a hydraulic lift mounted on wheels that can be easily moved from one location to another. This is the mobile scissor lift technical specifications:

Model | Platform Size (mm) | Lifting Height (m) | Load Capacity (kg) | Machine Weight (kg) | Overall Dimensions (mm) |

THCY-0.5-4 | 2010*830 | 4 | 500 | 670 | 2016*1000*1120 |

THCY-0.5-6 | 2010*830 | 6 | 500 | 800 | 2016*1000*1170 |

THCY-0.5-6.8 | 2010*830 | 6.8 | 500 | 800 | 2016*1000*1170 |

THCY-0.5-8 | 2010*830 | 8 | 500 | 960 | 2016*1000*1260 |

THCY-0.5-9 | 2010*830 | 9 | 500 | 1050 | 2016*1000*1480 |

THCY-0.5-10 | 2010*1130 | 10 | 500 | 1280 | 2016*1290*1540 |

THCY-0.3-11 | 2010*1130 | 11 | 300 | 1360 | 2016*1290*1660 |

THCY-0.5-12 | 2462*1210 | 12 | 500 | 1950 | 2465*1360*1780 |

THCY-0.5-14 | 2845*1420 | 14 | 500 | 2450 | 2845*1620*1895 |

THCY-0.3-16 | 2845*1420 | 16 | 300 | 2700 | 2845*1620*2055 |

THCY-0.3-18 | 3060*1620 | 18 | 300 | 3950 | 3060*1800*2120 |

THCY-1.0-4 | 2010*1130 | 4 | 1000 | 1000 | 2016*1290*1150 |

THCY-1.0-6 | 2010*1130 | 6 | 1000 | 1130 | 2016*1290*1310 |

THCY-1.0-8 | 2010*1130 | 8 | 1000 | 1380 | 2016*1290*1420 |

THCY-1.0-10 | 2010*1130 | 10 | 1000 | 1580 | 2016*1290*1620 |

THCY-1.0-12 | 2462*1210 | 12 | 1000 | 2400 | 2465*1360*1780 |

THCY-1.0-14 | 2845*1420 | 14 | 1000 | 2800 | 2845*1620*1895 |

Customization | ower: AC/DC/Diesel; Can add assisted walking device; Can add extended platform; Can add explosion-proof motor(AC or Diesel power); Can add remote control; Can add frequency changer; Can add hand pump; Can add alarm light, overload alarm, tilt alarm

| ||||

(3) Self-propelled scissor lift: it is an aerial work platform that is equipped with its own power source and can move vertically and horizontally without the need for external equipment or manpower. This is the mobile scissor lift technical specifications:

Model | Platform Size | Load Capacity | Lifting Height (m) | Overall Dimensions (mm) | Extended Platform | Machine weight |

THJZ-6B | 1730*740 | 200 | 6 | 1910*780*2120 | 0.9 | 1430kg |

THJZ-6 | 2270*1110 | 320 | 6 | 2470*1150*2200 | 0.9 | 2000kg |

THJZ-8 | 2270*1110 | 320 | 8 | 2470*1150*2320 | 0.9 | 2350kg |

THJZ-10 | 2270*1110 | 320 | 10 | 2470*1150*2430 | 0.9 | 2600kg |

THJZ-12 | 2270*1110 | 320 | 12 | 2470*1150*2550 | 0.9 | 2850kg |

THJZ-14 | 2640*1120 | 230 | 14 | 2850*1250*2640 | 0.9 | 3300kg |

THJZ-16 | 2260*1130 | 320 | 16 | 3150*1530*2350 | 0.9 | 3880kg |

Customization | Can add remote control; Load capacity can be 500kg; Color

| |||||

3. How To Operate a Scissor Lift?

Stationary scissor lift: It is fixed in ground, so the operation is very simple and easy, only need to add hydraulic oil and connect to power supply and it will work, you can make it up and down by remote controller & control button;

Mobile scissor lift:

The movement of mobile scissor lift depends on the operator dragging the front handle. Some friends may be curious about how to drag it? After all, the weight of such equipment is already very heavy. How to drag it only by the operator's strength?

The mobile scissor lift was designed with the problem of movement in mind. The drag handle and tire we designed can enable an adult woman to drag a mobile scissor lift of less than 8m. However, if the mobile scissor lift is too high and has a large weight, we recommend that you choose assisted walking. As the name suggests, assisted walking is to use batteries to assist operators to move the equipment. The handle with assisted walking is similar to the throttle handle of a motorcycle. Once twisted, the battery will provide power to drive the equipment to move, and there is a button switch to determine whether the equipment moves forward or backward. After explaining the moving problem, let's explain how to lift and what to pay attention to before lifting.

1. Inspection: When the platform is used for the first time (after long-distance transportation or long storage time), carefully check the hydraulic pipelines and electrical systems to ensure that there is no leakage in the hydraulic pipelines and joints and that the electrical circuits are not loose before use.

2. Open the outriggers: for absolute safety, the four legs must be firmly fixed on the horizontal ground before lifting. The outriggers should be fully opened to the baffle position and supported on a solid ground. It is strictly forbidden to use without supporting the outriggers.

3. There is a wired remote control on the table to control the lifting, and there is also a control button at the bottom to control the lifting. The remote control can also be customized according to customer requirements for remote control lifting.Turn on the main power switch and the upper control switch, and run the platform normally after 3 times without abnormality.

Self-propelled scissor lift:

The self-propelled scissor lift is a fully automatic scissor lift, which is very easy to operate. It moves by a wired remote control on the platform, and can be moved by remote control without the need for human dragging. The lifting and lowering can also be operated by a remote control. The self-propelled scissor lift can be moved and adjusted when operating at high altitudes. The self-propelled scissor lift relies on batteries as a driving force for lifting and moving. The batteries are lead-acid batteries. It usually takes 8 hours to fully charge, and the normal working time can reach 6-8 hours.

1. Equipment inspection:

Appearance inspection: Before operation, it is necessary to conduct a comprehensive inspection of the appearance of the equipment, including the platform, wheels, guardrails, hydraulic system and other parts to ensure that there is no obvious damage or abnormality.

Hydraulic oil tank: Check whether the oil level in the hydraulic oil tank is within the normal range. If necessary, add hydraulic oil of the same type.

Battery power: Confirm that the battery power is sufficient to ensure the normal operation of the equipment.

Safety device: Check whether various safety devices, such as emergency stop button, overload alarm, etc., are working properly.

Operating system: Confirm that the operating system has no faults and the functions of control handles, buttons, etc. are normal.

2. Turn on the red emergency stop switch and select upper control or lower control

Walking: The handle on the platform can be used to realize the forward, backward, steering and other operations of the equipment.

Up & down: The lifting and lowering operation of the platform is realized through the up and down buttons on the console. Release the button to stop lifting after reaching the required height.

How to choose a scissor lift that is more suitable for us?

You can leave a message directly on the official website of JNHC Lift or contact us by phone. We will have professional technicians to recommend or customize the most suitable product for you according to your actual requirements.

920.webp)

606.webp)

235.webp)